Your patent is called »Multilayer ceramic assembly technology for high-frequency systems«. What does that mean?

In the past, our modules for radar and communication applications were manufactured in a complex and expensive way using waveguide technology. Each module has to be precisely milled individually in complex work. This is why we have been using printed circuit boards for several years that are inexpensive and easy to manufacture. These work very well up to 100 GHz. At higher frequencies, however, the performance drops dramatically. There was no alternative to waveguides – until now.

»With multilayer ceramics, so-called low temperature cofired ceramics LTCC, we can realize high-frequency systems similar to printed circuit boards at lower cost, which work up to over 300 GHz. Everyone today talks about communication applications such as 5G and 6G, which use high frequencies, but how such systems can be built cost-effectively is not yet clear. Our technology could be the solution. We hope that at best we can revolutionize the assembly technology.«

How does this new assembly technology work in comparison to the previous one?

A printed circuit board consists of a substrate, typically a fiberglass-reinforced plastic. For high frequencies, on the other hand, special liquid crystal polymer substrates are used. Here, copper is applied on both sides and structured, i.e. the parts that are not needed are etched away. The components are then applied.

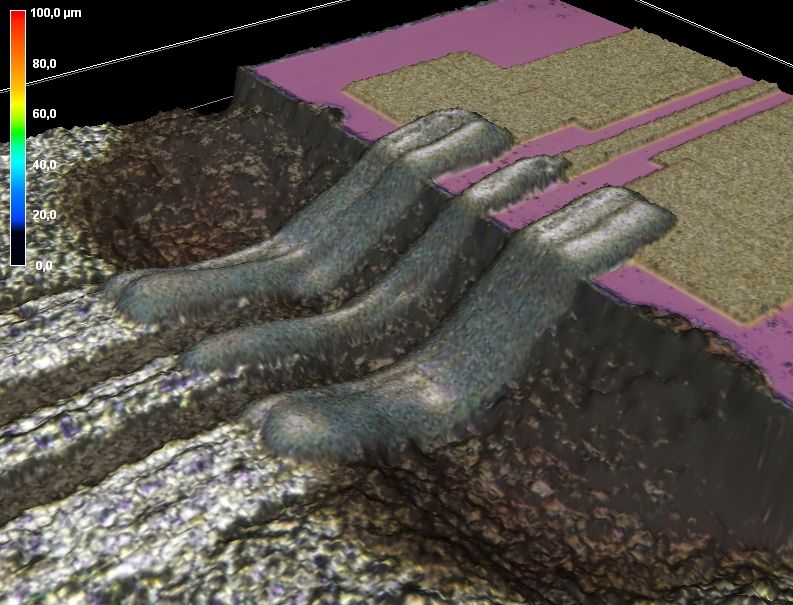

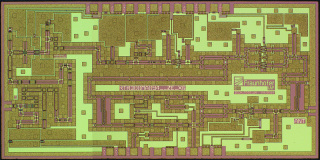

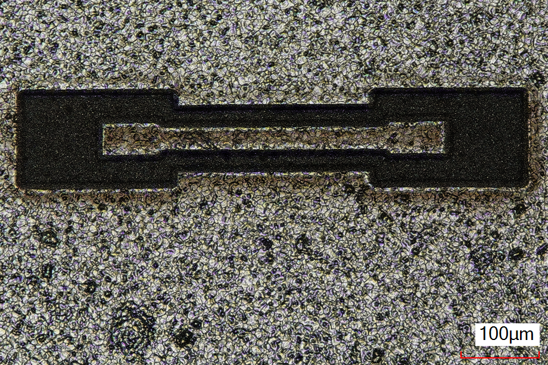

»The structure on a ceramic board works very similarly. You start with a wafer-thin layer of LTCC. However, instead of etching the copper surfaces, silver ink is printed by aerosol jet printing. The great thing is that very fine structures can be applied with this technique. Finer than they could be etched today with copper and finer than they could be produced with another printing process.«

Another huge advantage is that bond processes are no longer necessary. Previously, the chip was inserted on the circuit board and then contacted with bonding wires. This is technically very complex and also leads to losses starting at around 100 GHz being so high that the system is no longer efficient. Our idea now is that the chip is located in the ceramic and the printer then prints the conductor paths on the ceramic. It does not stop at the chip, but simply prints over it – so the silver ink automatically establishes the contact. We are developing this method further in the »TeraKer« project.

Fraunhofer Institute for Applied Solid State Physics IAF

Fraunhofer Institute for Applied Solid State Physics IAF