In this interview, PhD students Anli Ding and Niclas Feil talk about their collaboration on a patent for surface acoustic wave resonators based on aluminum scandium nitride (AlScN), which they applied for in 2020.

You are both doing research on the semiconductor material aluminum scandium nitride (AlScN), how did you join IAF/INATECH and get involved in this topic?

Anli — Sometimes, I am surprised myself that I got into applied physics at Fraunhofer IAF, since I started with a bachelor’s degree in material studies in China. Back then, I heard about the degree program Microsystem Engineering at the University of Freiburg. Its good reputation and close contact to industry convinced me to move to Germany for my master’s degree. Thanks to the close collaboration between University and Fraunhofer, I got the opportunity to write my thesis at Fraunhofer IAF and afterwards I got the offer to do my dissertation on AlScN, which I gladly took.

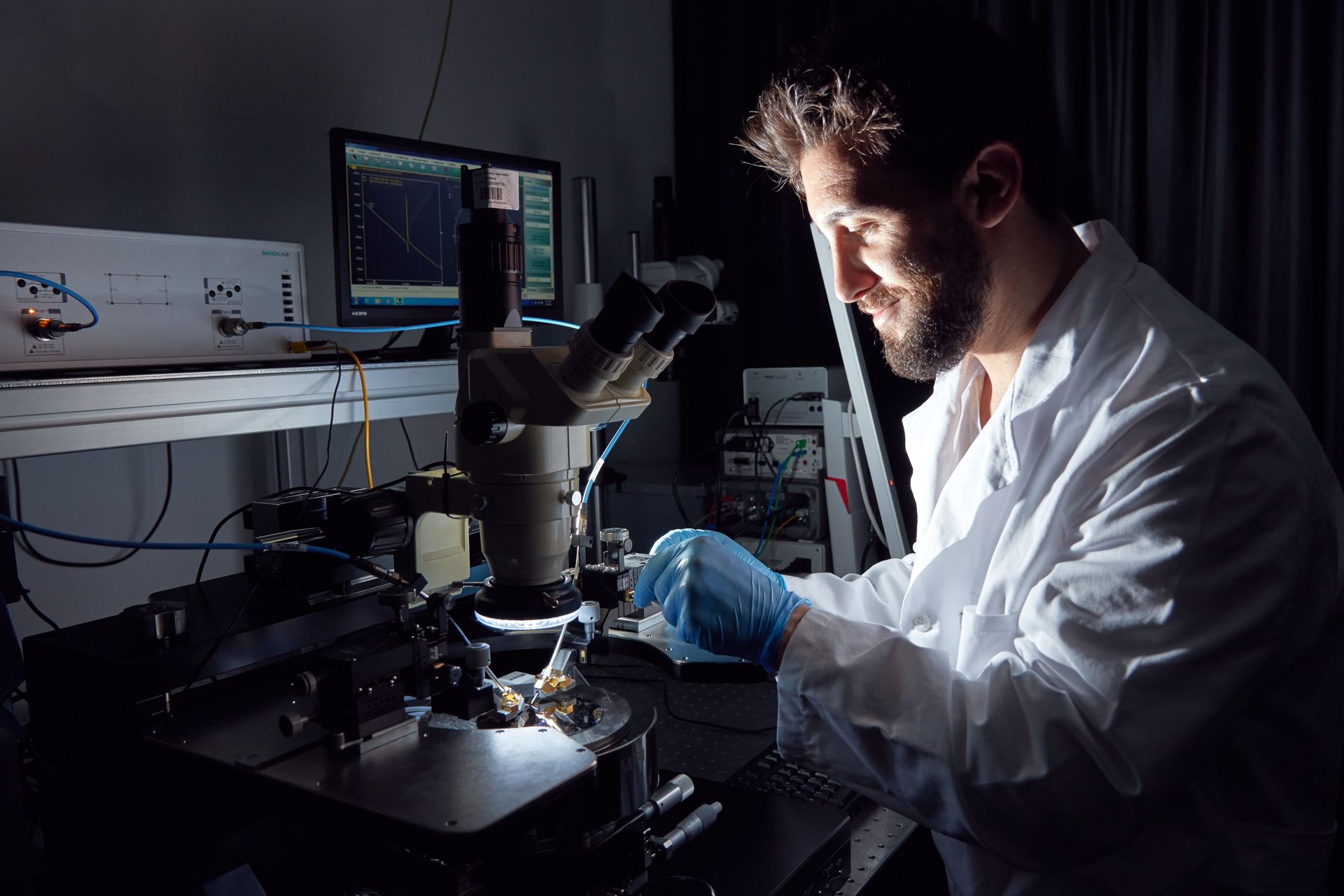

Niclas — Right from the start of my studies, I was particularly interested in crystallography. Piezoelectric acoustic waves are an exciting area of research in which the elastic and piezoelectric properties of crystals are used to describe, for example, surface waves on a crystal surface, similar to those on a water surface. I came across the topic of AlScN during a lecture on compound semiconductors given by Professor Oliver Ambacher. That’s where I first learned about the material and it immediately caught my attention. After the lecture, I directly asked if it was possible to do research in this area. This way I came to my master’s thesis and now also my doctorate at the Department of Sustainable Systems Engineering INATECH, where Professor Ambacher teaches.

What are surface acoustic wave filters based on AlScN and what are the advantages and challenges of the material?

Niclas — The basic material aluminum nitride (AlN) has been known for a relatively long time. It is used, for example, in mobile communications, in so-called bulk acoustic resonators. Essentially, it depends on the crystal structure of the atoms; in the case of AlN, these crystallize in the so-called wurtzite structure. Due to the atomic arrangements of the structure, the crystal has a polarization, which means that it is a pyroelectric, and thus also piezoelectric crystal. This is related to an important property: the electromechanical coupling. It essentially defines the bandwidth of a piezoacoustic filter.

If scandium is added by partially replacing the Al atoms with Sc, the piezoelectric effect is greatly increased by deformation of the crystal lattice, especially for the c-axis of the crystal. To realize these properties, which are already used in bulk filters, for surface acoustic wave (SAWs) based applications, is the idea behind our research.

Anli — Fraunhofer IAF has many years of experience researching AlScN. We could already grow AlScN with good crystal quality and high scandium concentrations in previous research projects. However, we previously only grew c-plane AlScN, which means that the piezoelectric axis is perpendicular to the substrate. This allows for high performance bulk acoustic resonators, but not for SAWs. So we had to find a way to tilt the c-axis of the AlScN about 90° to capitalize on the great potential of AlScN for SAW resonators.

Fraunhofer Institute for Applied Solid State Physics IAF

Fraunhofer Institute for Applied Solid State Physics IAF